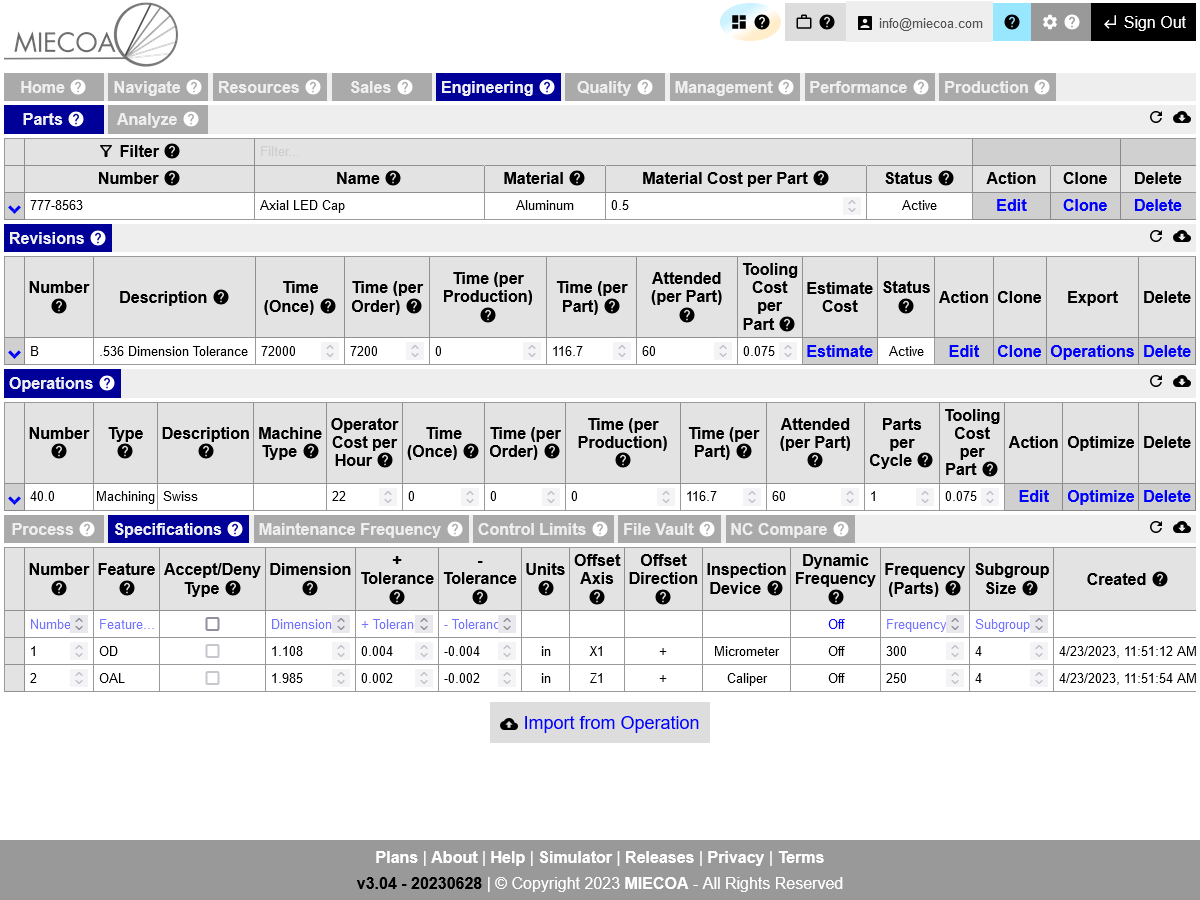

DIGITIZE

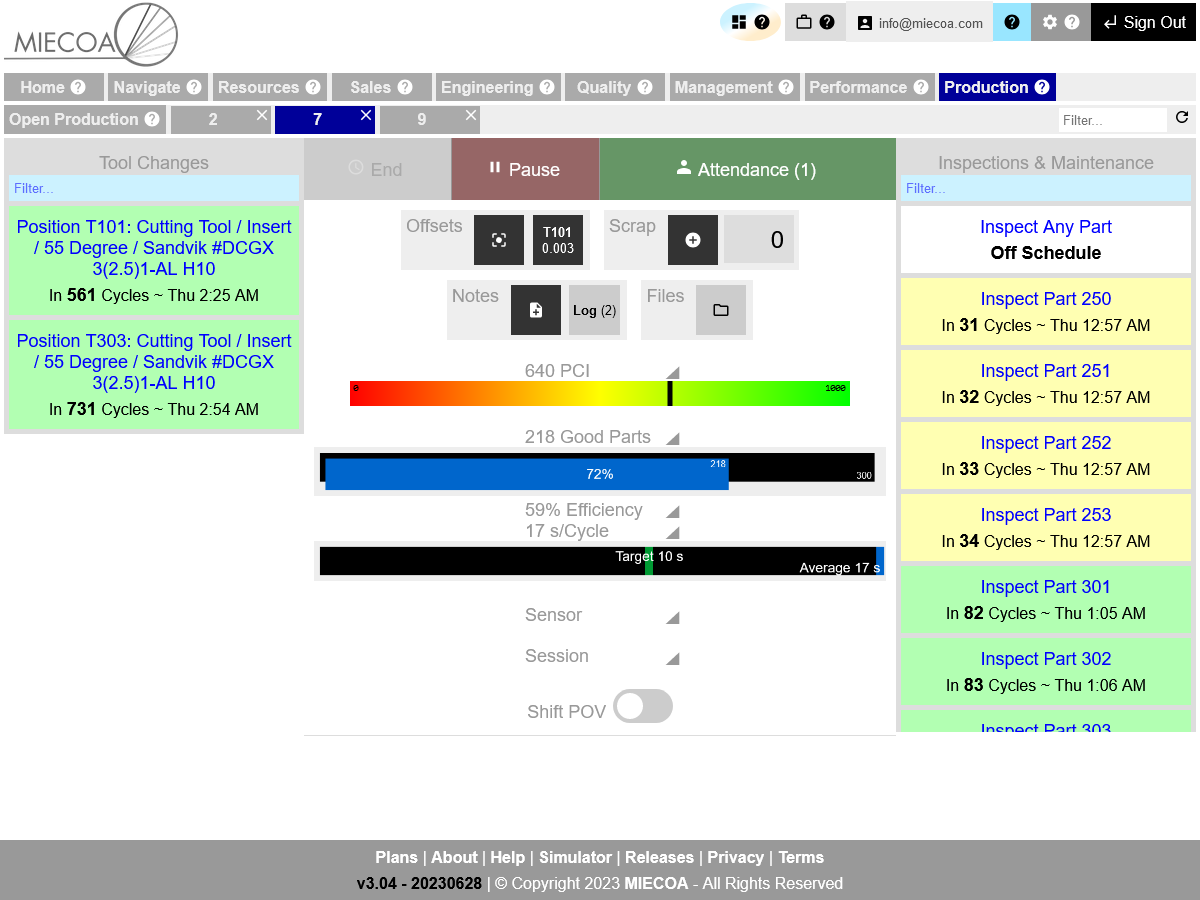

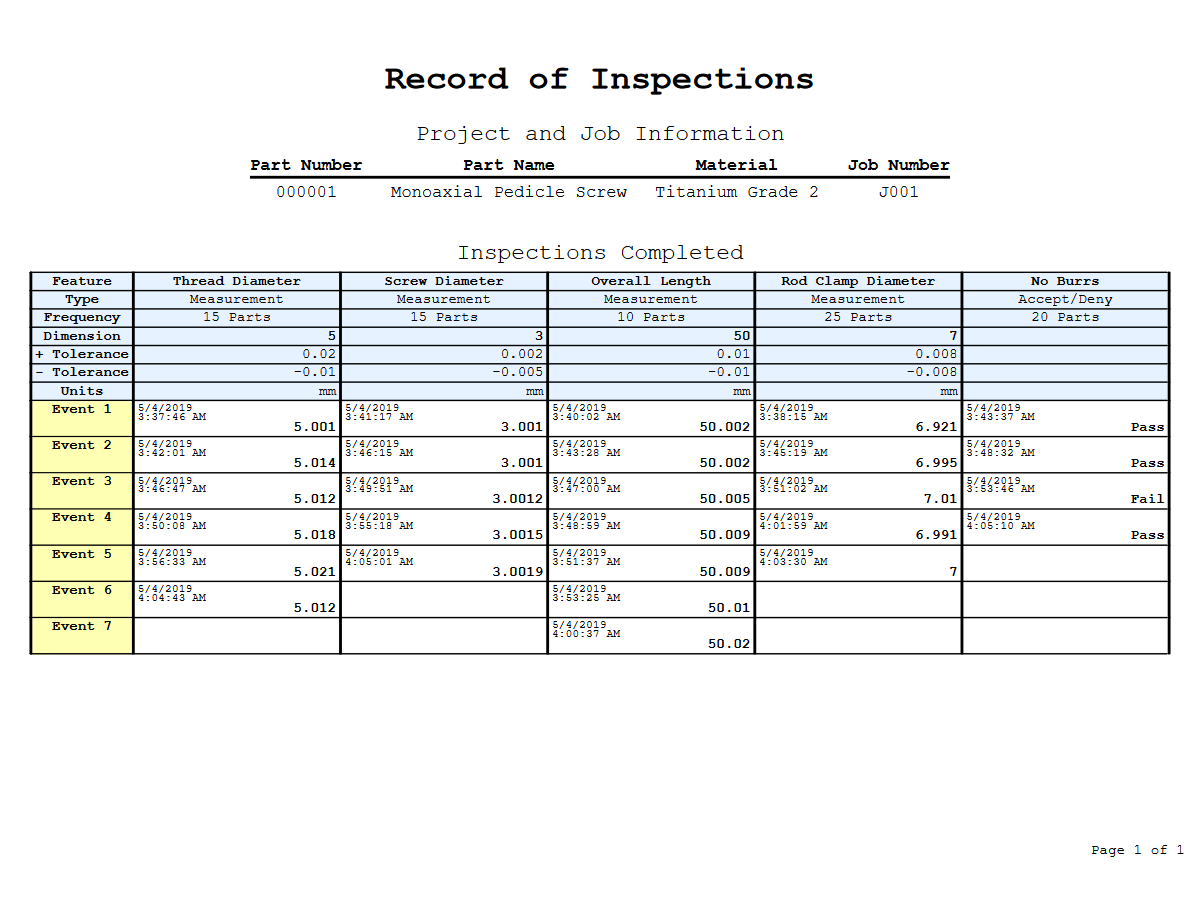

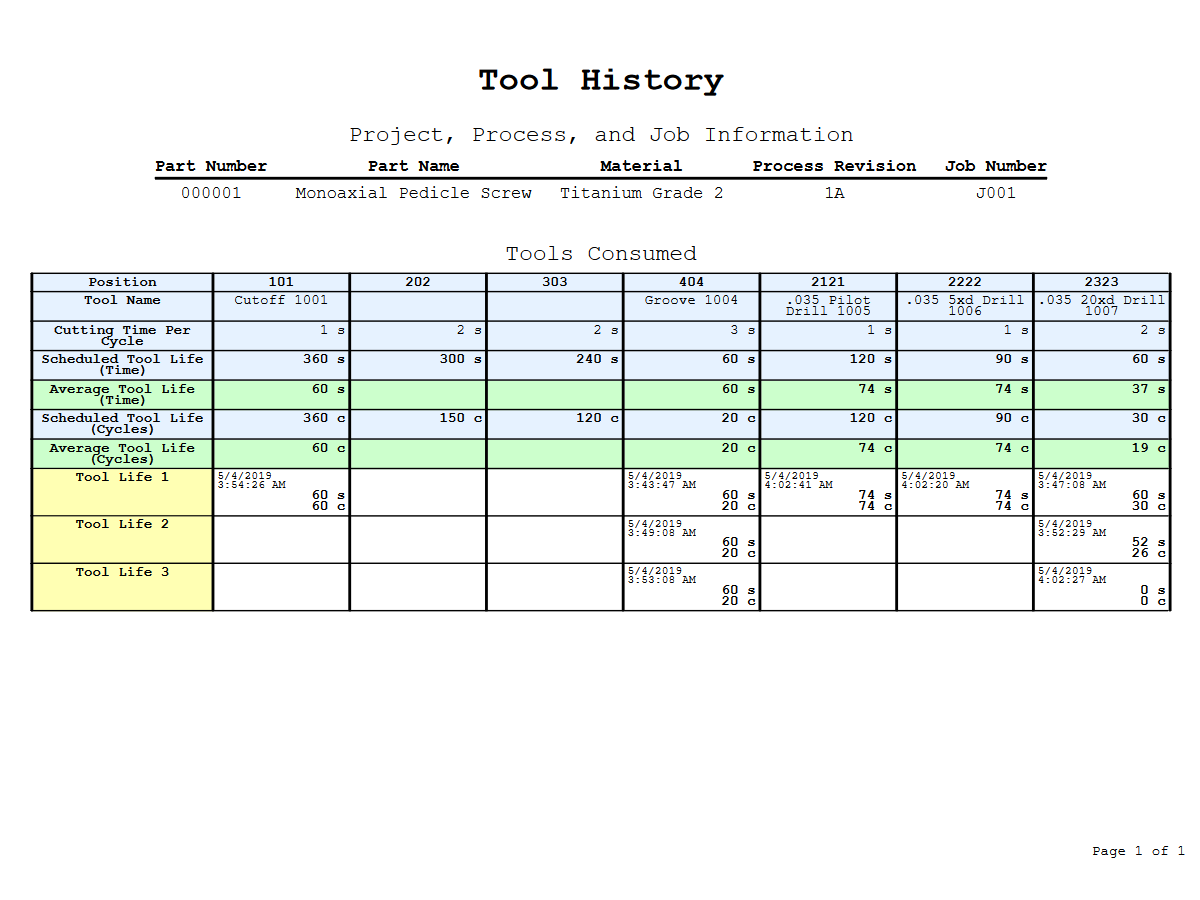

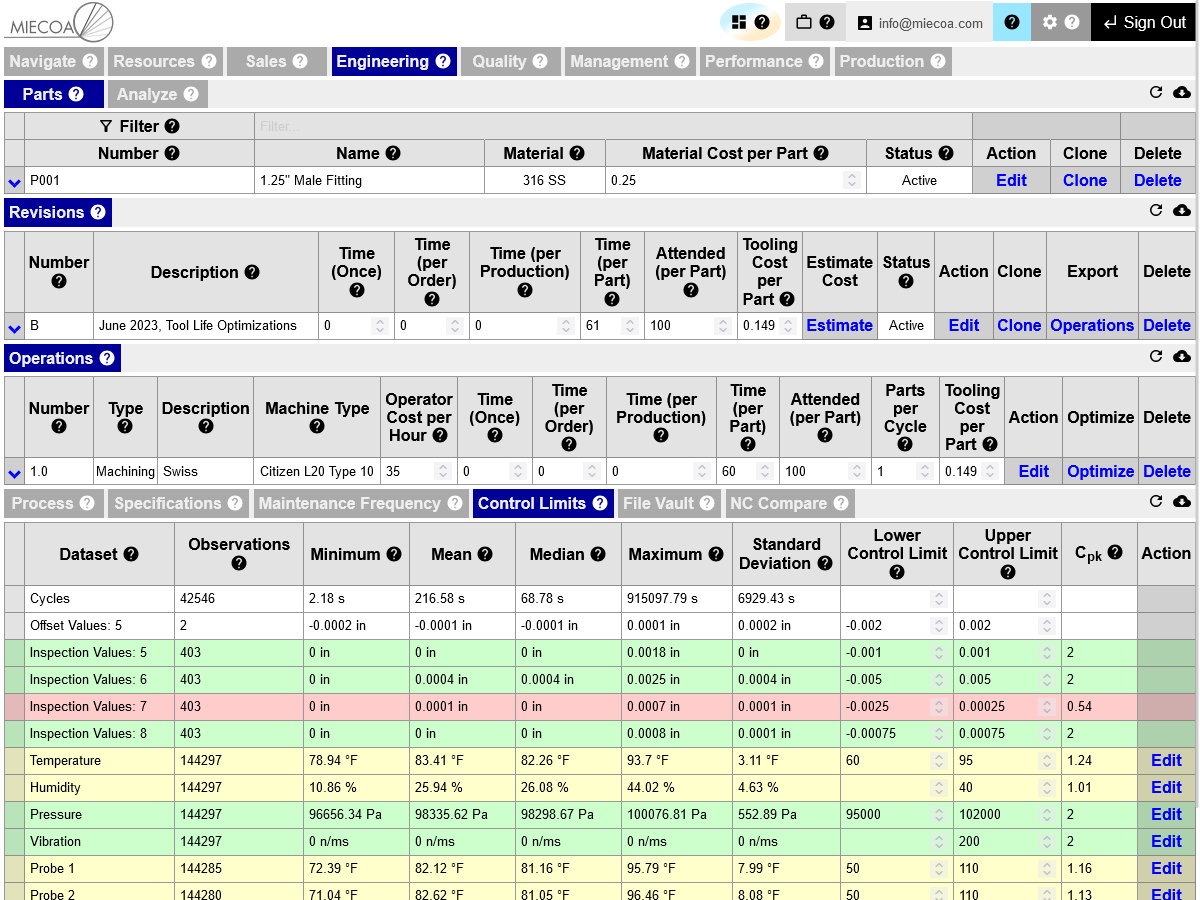

Electronic documentation of process versions, production sessions, and time-stamped machining events like scrap, tool changes, inspections, offsets, maintenance, and notes.

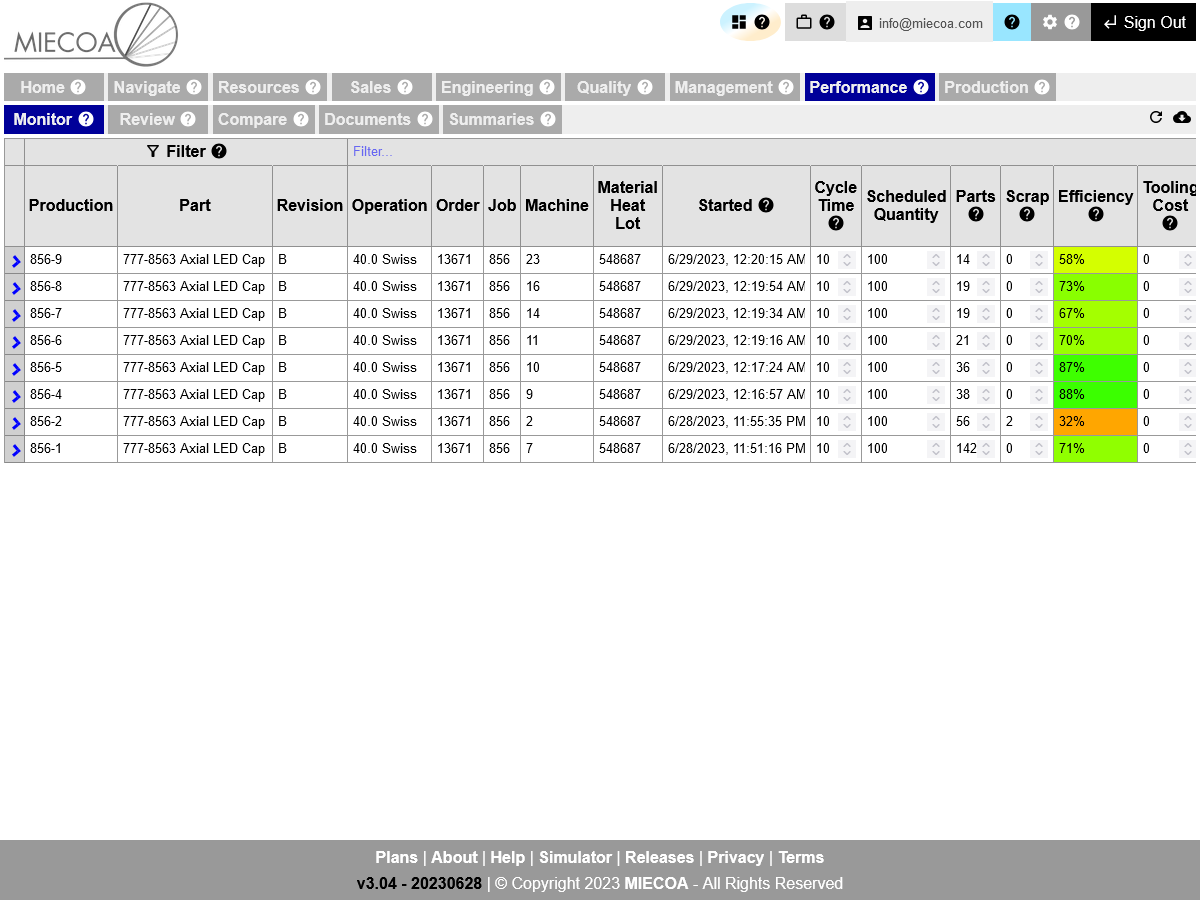

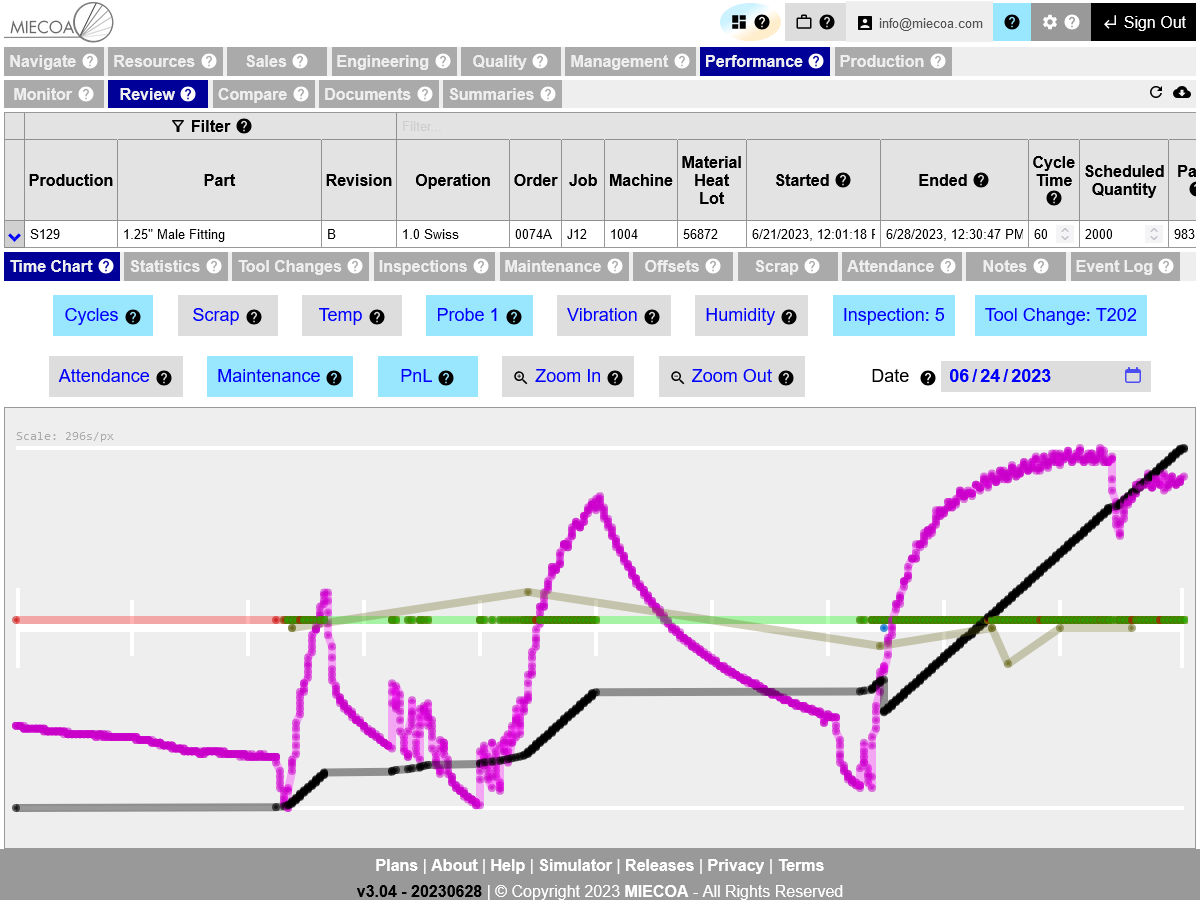

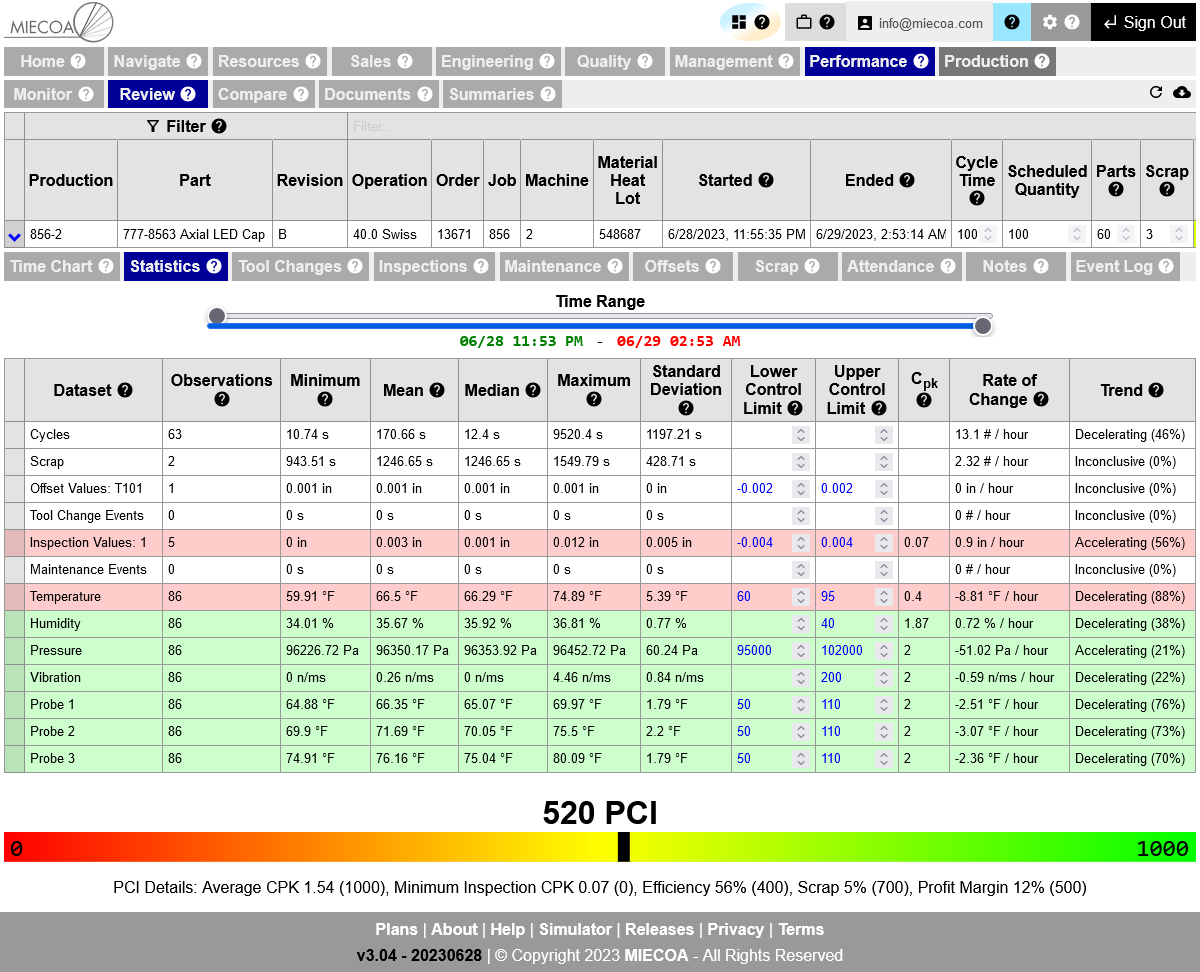

SUPERVISE

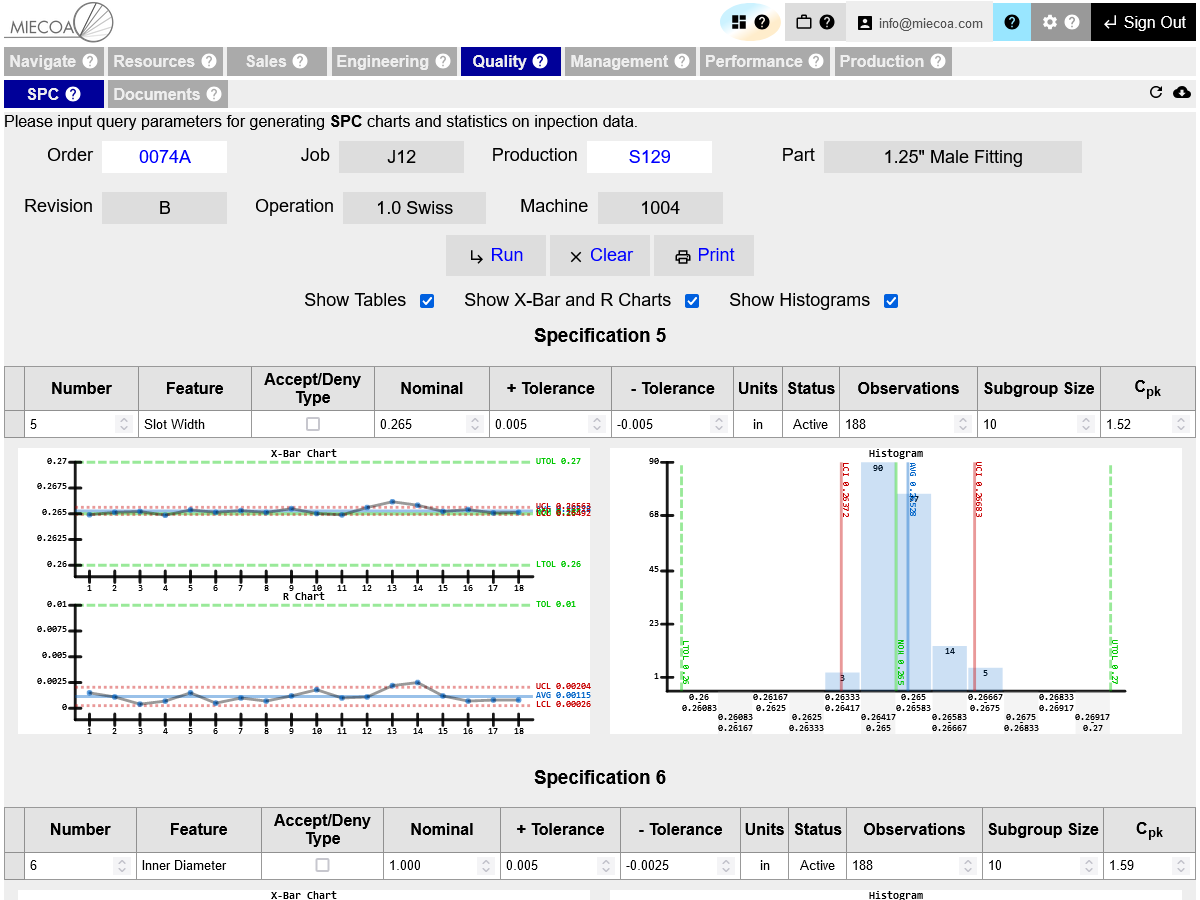

Effortlessly monitor shop-wide status and capability using tables, time-charts, and dashboards. Watch as patterns emerge in the complex equation of uptime, tool life, insepection frequencies, and scrap generation.

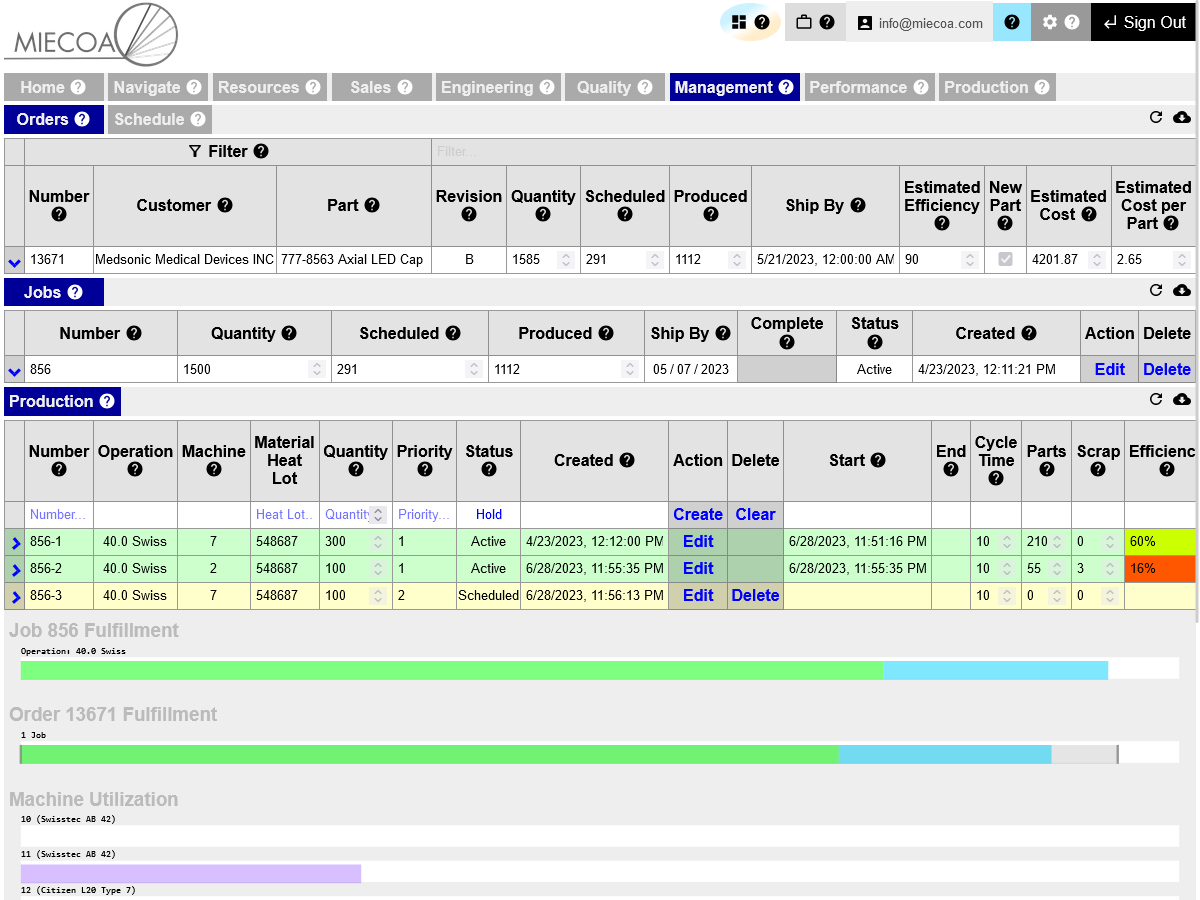

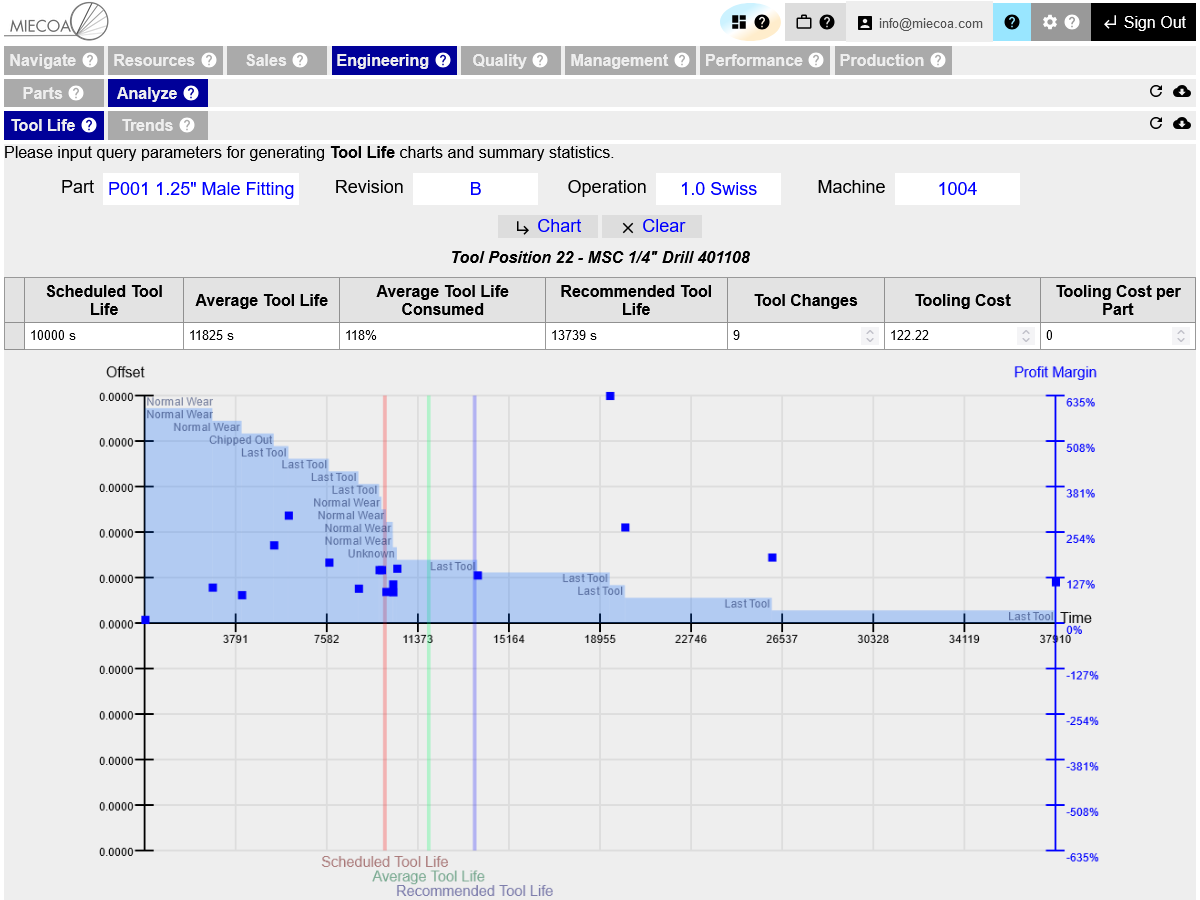

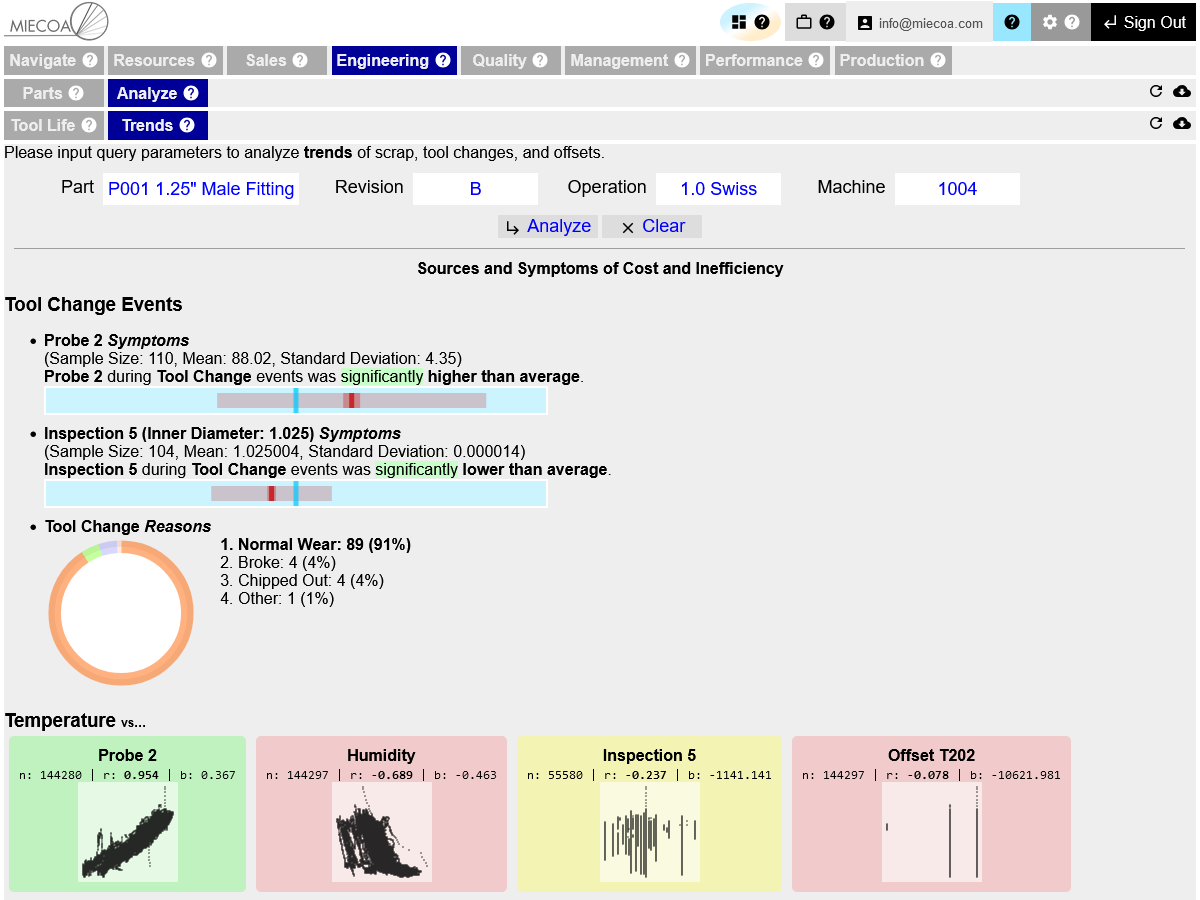

OPTIMIZE

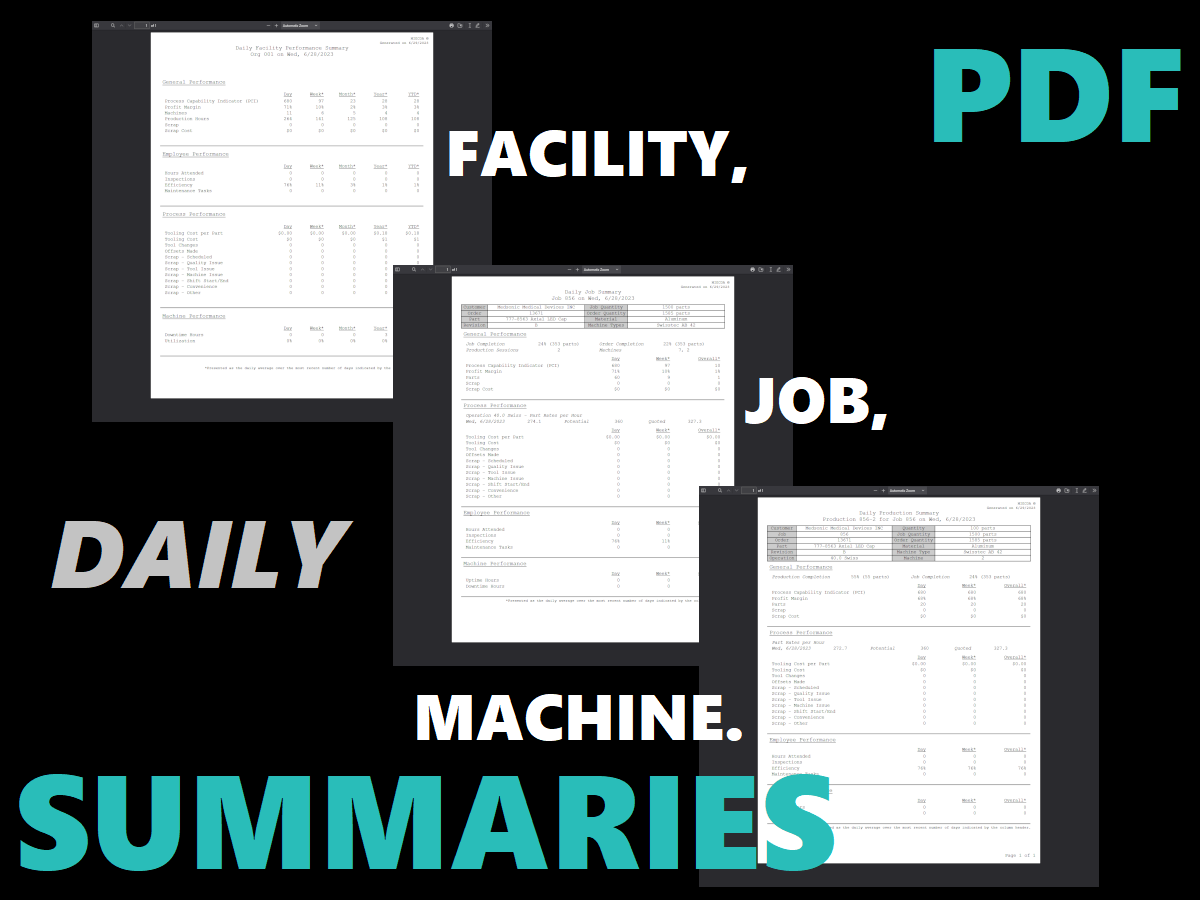

Capture the complete picture of your facility with well-defined data streams from human and non-human sources. Watch for random improvements, run dedicated experiments, or let the graphs, reports, and suggestions guide your incremental growth.

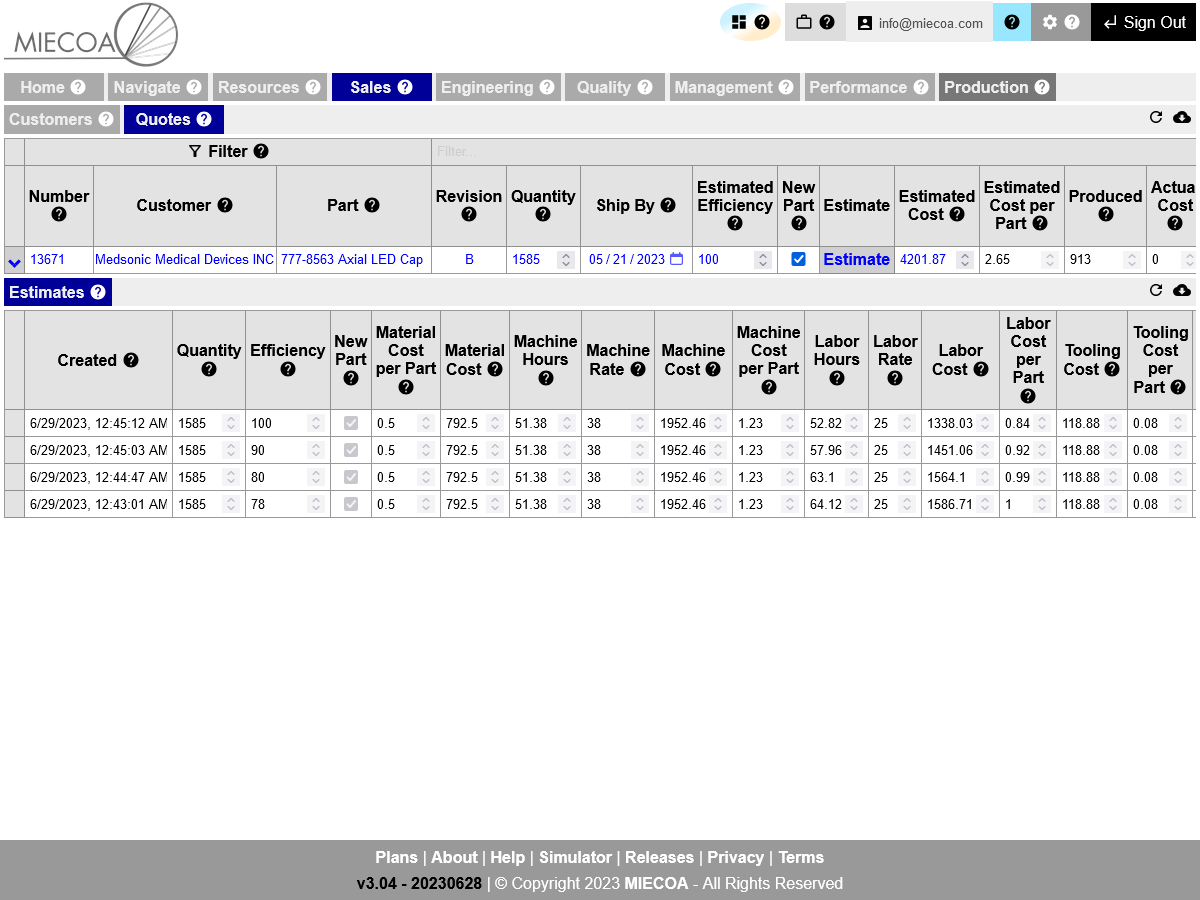

CENTRALIZE

Cloud-based consolidation of knowledge from all departments and operations alleviates unnecessary redundancy experienced with dual-entry and email chains. Chat, notifications, and daily summaries, in addition to a relational database dedicated to manufacturing, creates effortless transparency.